SFH achievements

Chip processing, filtration & hydraulics...

SFH

Discover all the achievements of S.F.H.

Discover all the SFH achievements

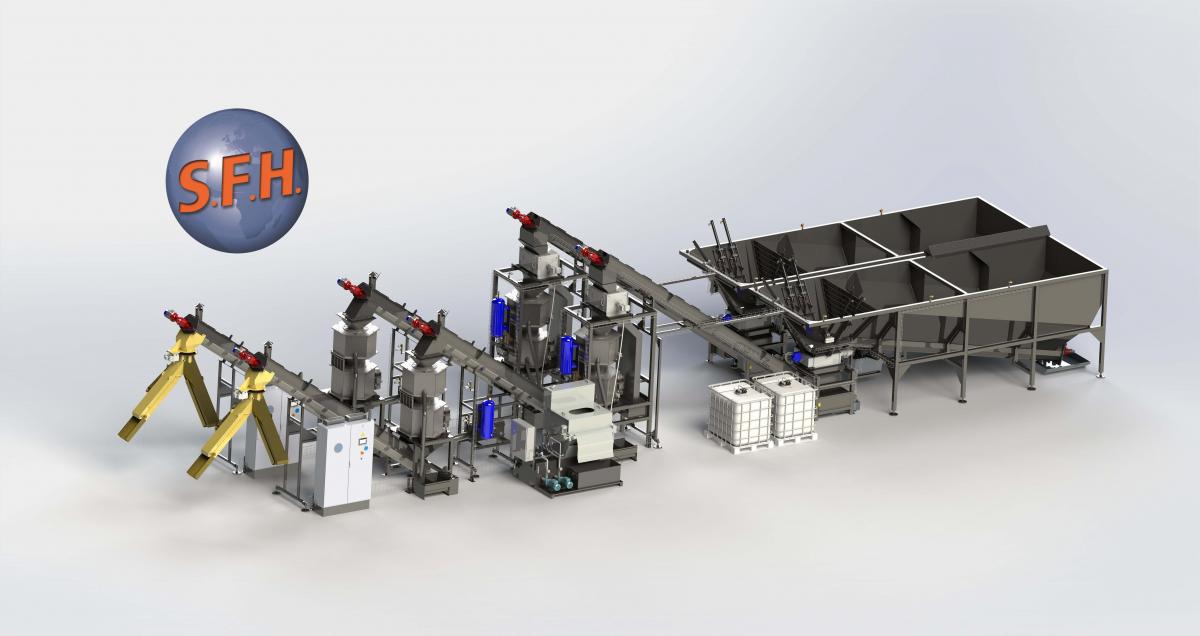

SFH chip processing line presentation

Details

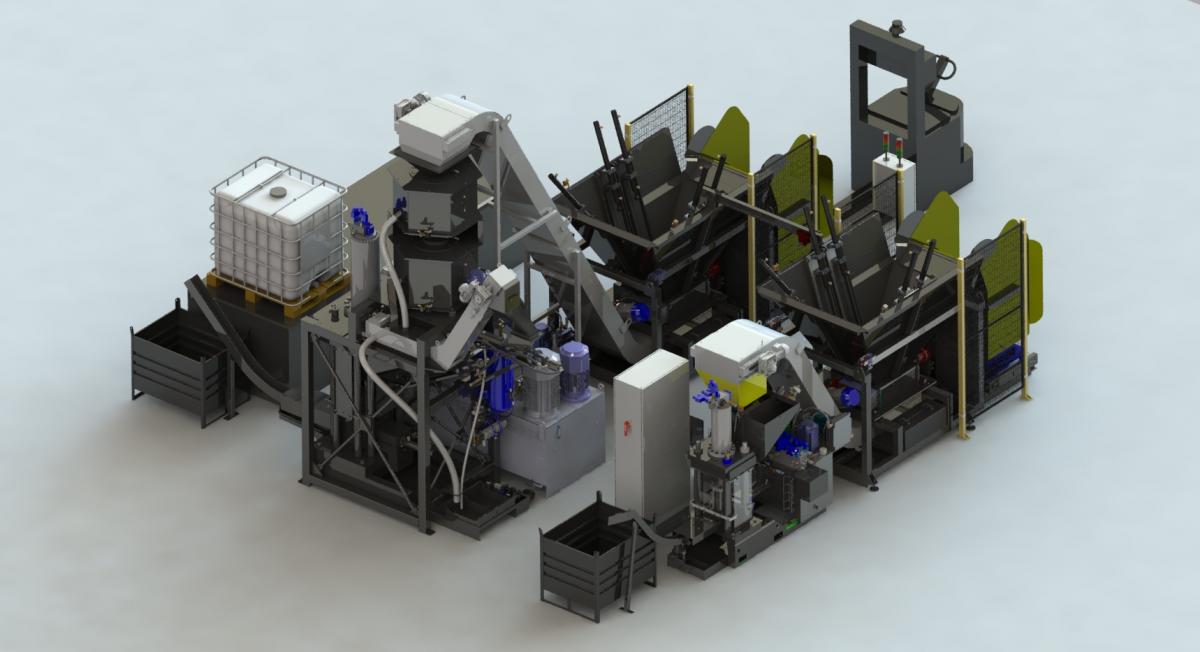

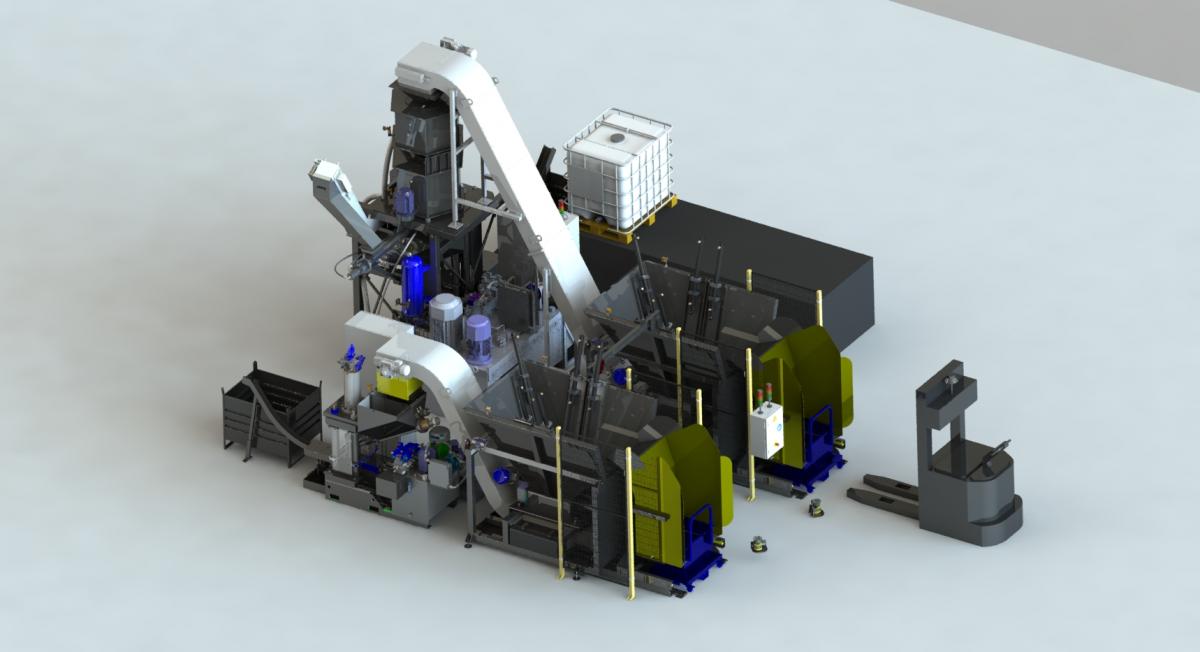

Steel and stainless steel birdnest chip treatment

Processing line for chips for stainless steel turnings from the manufacture of hydraulic fittings. The operator inserts his chip trolley into the trolley tilter and launches the machine cycle. The machine works independently. It shred the balls of chips before taking it to the wringer via a scraper conveyor. The chips are then compacted to be remelted. The oils are recovered and sent back to the machines.

Details

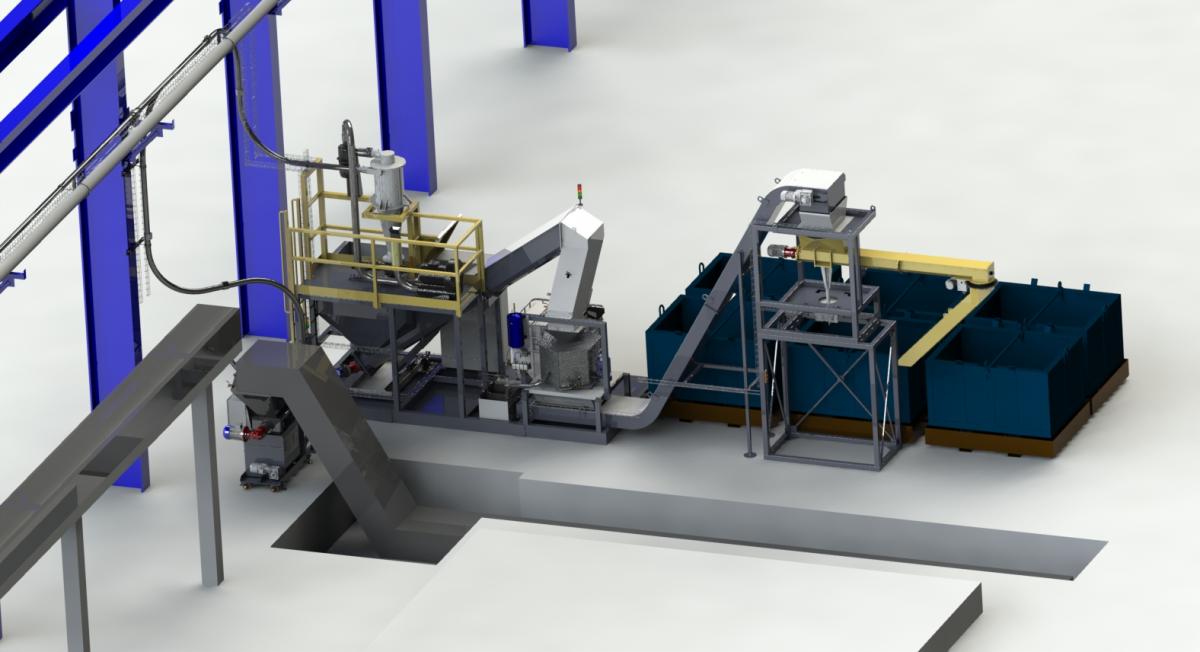

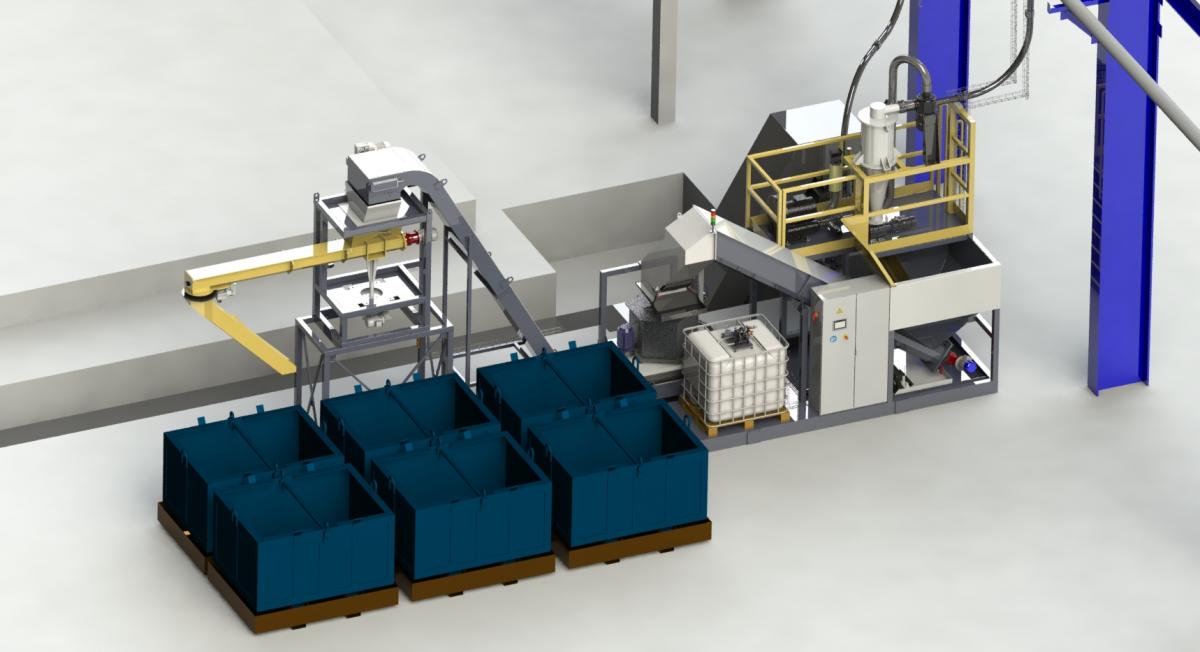

Aeronautic industry #3

We automatically recover the chips directly from the machine conveyor via a vacuum system that brings them back to the processing line. The chips are separated into two grades and then pass through the wringer. Then the line distributes the chips in different bins.

Details

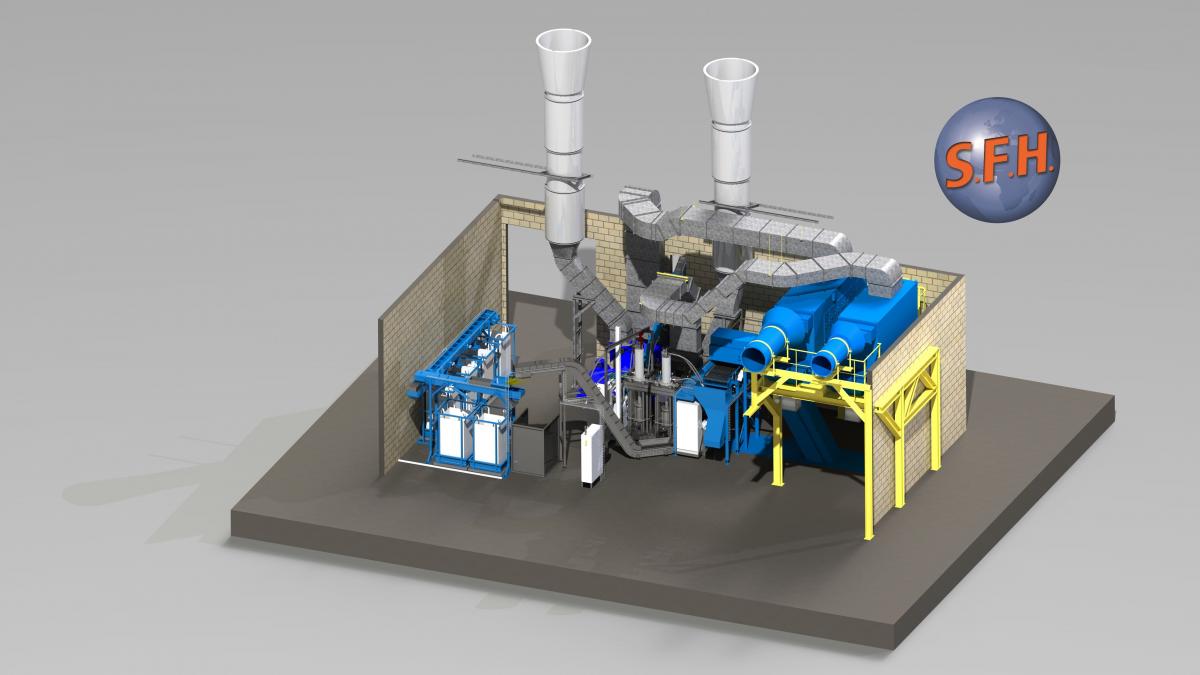

Titanium chip processing line for a foundry

Thanks to this complete processing line, we are able to achieve a moisture rate below 0,1%.

Details

Aluminium lithium chip processing line

Chip processing line 4.0, connected to the production line supervision. The line then divides the briquettes into Big-Bags, these are weighed and an associated delivery note is printed.

Details

Recovery of aluminium stamping scrap

Shredding of the skeletons then wringing out to recover the stamping oils. Finally, the briquettes are compacted and divided into different Big-Bags.

Details

Trommel bar for turning application

Separation line between brass fines and bar ends from turning machines.

Details

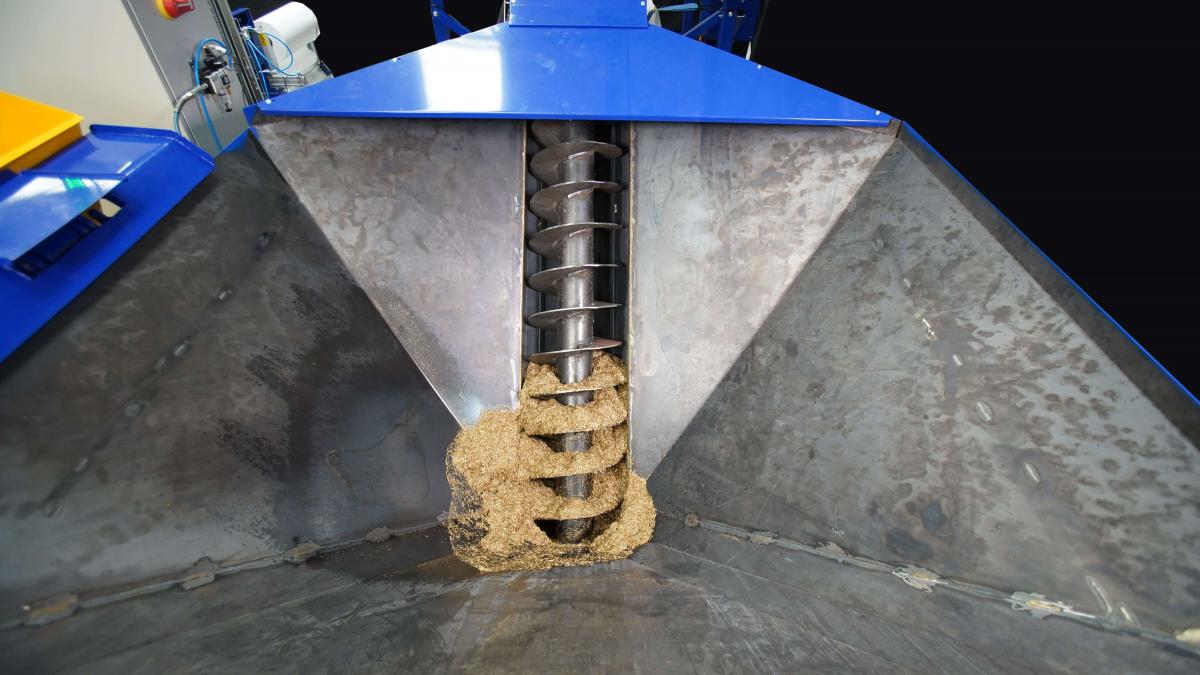

Treatment of brass chips with a 40m3 storage unit and double centrifuge

As the customer's chips are sent by sea container to its outlet, this line allows the wringing out and therefore the recovery of cutting oils, but also the optimisation of the container loading by optimising the filling of the container.

Details

Aluminium chip processing line with shredding and compacting units

Shredding and briquetting chip processing system for a recycling service provider.

Details

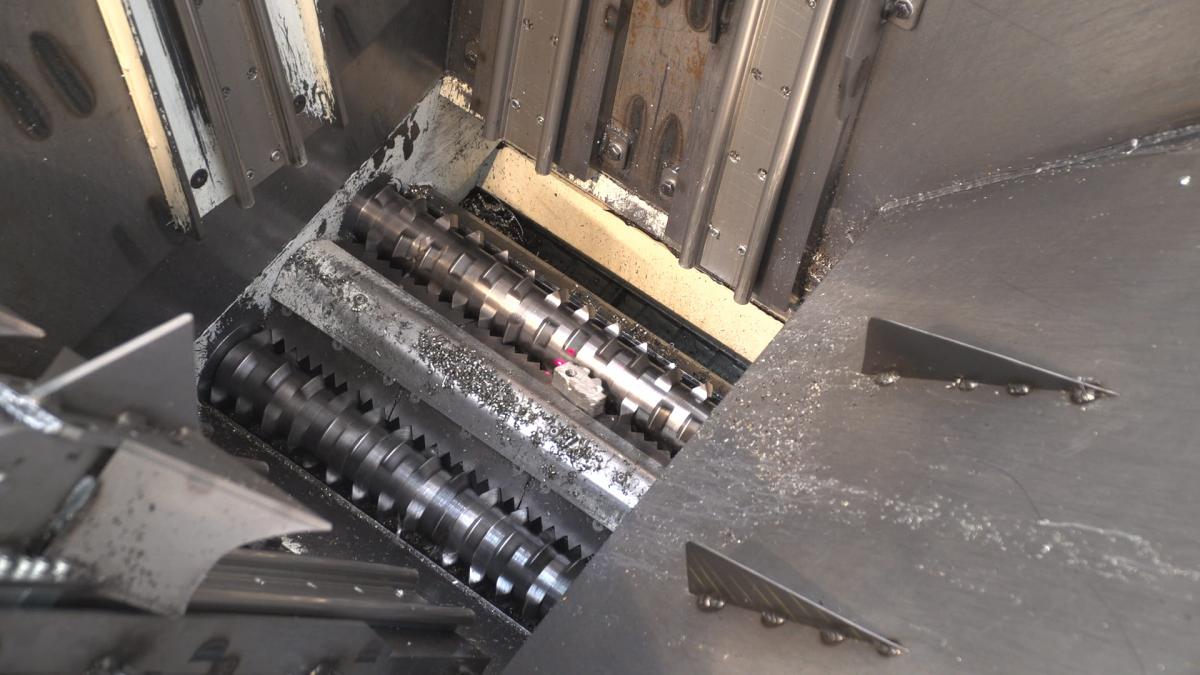

Shredding and centrifugation steel chip processing line

Chip processing line to recover cutting oils from steel chips for this customer.

Details

Chip suction and aerolic chips removal

Details

Chip compactor unit

Details

Chip processing line with a vertical conveyor, shredder and centrifugation unit

The fully automatic management of this line allows for the highest possible revaluation of both grades of chips and the recovery of both cutting fluids through a single machine. This unit has been designed with an automatic ejection system for foreign parts. This limits the risk of malfunctioning.

Details

Mobile chip processing container

The concept is a modular and mobile chip recycling station for high management capacity that can operate 24 hours a day in automatic mode and process the entire volume of chips of a production line, a workshop or an entire factory.

Details

Stainless steel chip processing line

This line recycles stainless steel chips for a group that manufactures watch cases for the Swiss watchmaking industry.

Details

Processing line for chips for stainless steel turnings from the manufacture of hydraulic fittings. The operator inserts his chip trolley into the trolley tilter and launches the machine cycle. The machine works independently.

Processing line for chips for stainless steel turnings from the manufacture of hydraulic fittings. The operator inserts his chip trolley into the trolley tilter and launches the machine cycle. The machine works independently.

Processing line for chips for stainless steel turnings from the manufacture of hydraulic fittings. The operator inserts his chip trolley into the trolley tilter and launches the machine cycle. The machine works independently.

Processing line for chips for stainless steel turnings from the manufacture of hydraulic fittings. The operator inserts his chip trolley into the trolley tilter and launches the machine cycle. The machine works independently.

Processing line for chips for stainless steel turnings from the manufacture of hydraulic fittings. The operator inserts his chip trolley into the trolley tilter and launches the machine cycle. The machine works independently.

Processing line for chips for stainless steel turnings from the manufacture of hydraulic fittings. The operator inserts his chip trolley into the trolley tilter and launches the machine cycle. The machine works independently.

Processing line for chips for stainless steel turnings from the manufacture of hydraulic fittings. The operator inserts his chip trolley into the trolley tilter and launches the machine cycle. The machine works independently.

Aeronautic industry

Aeronautic industry 1

Thanks to this complete processing line, we are able to achieve a moisture rate below 0,1%.

Thanks to this complete processing line, we are able to achieve a moisture rate below 0,1%.

Thanks to this complete processing line, we are able to achieve a moisture rate below 0,1%.

Chip processing line 4.0, connected to the production line supervision. The line then divides the briquettes into Big-Bags, these are weighed and an associated delivery note is printed.

Chip processing line 4.0, connected to the production line supervision. The line then divides the briquettes into Big-Bags, these are weighed and an associated delivery note is printed.

Chip processing line 4.0, connected to the production line supervision. The line then divides the briquettes into Big-Bags, these are weighed and an associated delivery note is printed.

Chip processing line 4.0, connected to the production line supervision. The line then divides the briquettes into Big-Bags, these are weighed and an associated delivery note is printed.

Recovering of aluminium stamping scrap

Separation line between brass fines and bar ends from turning machines.

Separation line between brass fines and bar ends from turning machines.

Separation line between brass fines and bar ends from turning machines.

Separation line between brass fines and bar ends from turning machines.

Treatment of brass chips with a 40m3 storage unit and double centrifuge

Treatment of brass chips with a 40m3 storage unit and double centrifuge

Treatment of brass chips with a 40m3 storage unit and double centrifuge

Aluminium chip processing line with shredding and compacting units

Aluminium chip processing line with shredding and compacting units

Aluminium chip processing line with shredding and compacting units

Aluminium chip processing line with shredding and compacting units

Aluminium chip processing line with shredding and compacting units

Shredding and centrifugation steel chip processing line

Shredding and centrifugation steel chip processing line

Shredding and centrifugation steel chip processing line

Shredding and centrifugation steel chip processing line

Shredding and centrifugation steel chip processing line

Shredding and centrifugation steel chip processing line

This line recycles stainless steel chips for a group that manufactures watch cases for the Swiss watchmaking industry.

This line recycles stainless steel chips for a group that manufactures watch cases for the Swiss watchmaking industry.

This line recycles stainless steel chips for a group that manufactures watch cases for the Swiss watchmaking industry.

This line recycles stainless steel chips for a group that manufactures watch cases for the Swiss watchmaking industry.

This line recycles stainless steel chips for a group that manufactures watch cases for the Swiss watchmaking industry.